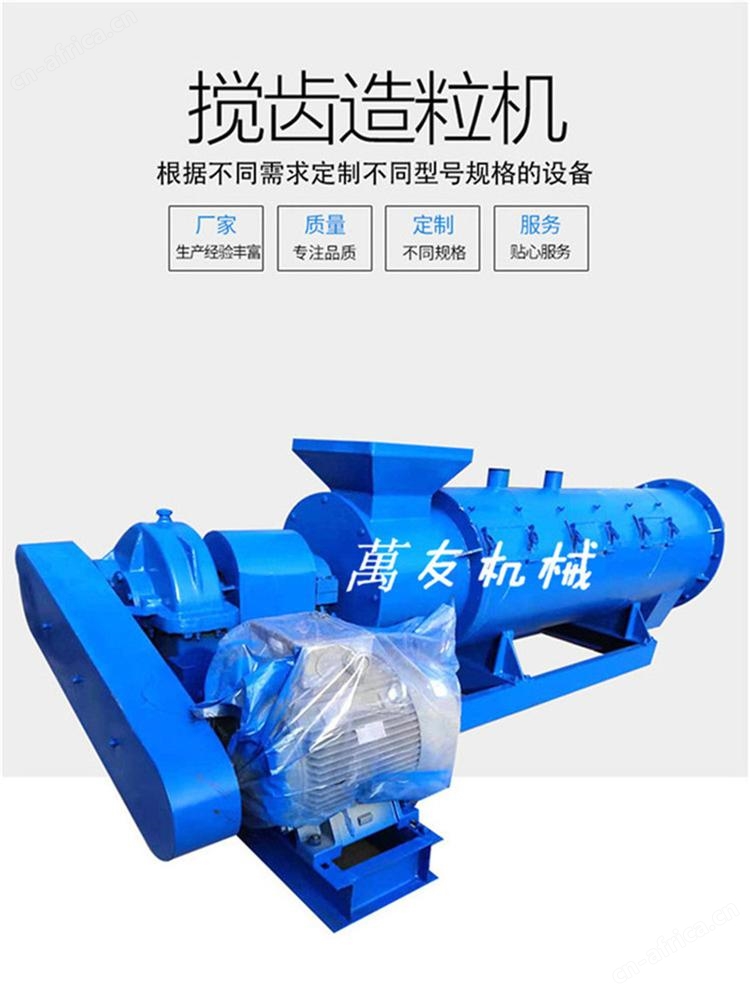

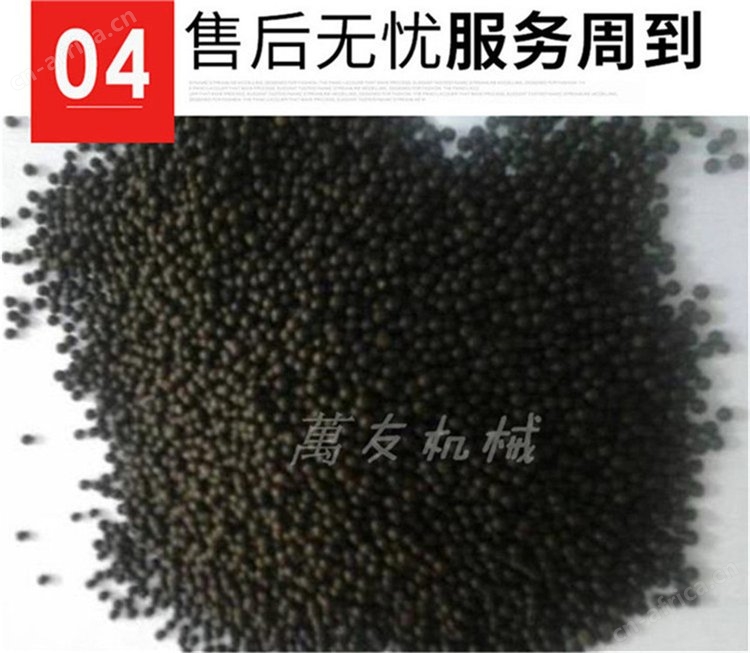

搅齿造粒机造粒原理:利用高速回转的机械搅拌力及由此产生的空气动力,使细粉状料在机内连续实现混合、碰撞、粘连、成粒、球化、致密等过程,从而达到造粒的目的。颗粒形状为球形,球形度≥0.7,粒径一般在0.3-3毫米之间,成粒率≥85%,颗粒直径的大小可通过物料混合量和主轴转速适当调节,通常混合量越低,转速越高,颗粒越小,反之亦然。

搅齿造粒机造粒原理:利用高速回转的机械搅拌力及由此产生的空气动力,使细粉状料在机内连续实现混合、碰撞、粘连、成粒、球化、致密等过程,从而达到造粒的目的。颗粒形状为球形,球形度≥0.7,粒径一般在0.3-3毫米之间,成粒率≥85%,颗粒直径的大小可通过物料混合量和主轴转速适当调节,通常混合量越低,转速越高,颗粒越小,反之亦然。

搅齿造粒机主要适应范围:草炭、污泥、鸡粪、牲畜粪、杂草、树叶、食品残渣、糟渣饼粕、秸杆发酵等,为原料的生物有机肥造粒,也可用玉米粉、豆类粉、草粉等生产混合饲料制粒。

新型搅齿造粒机利用高速回转的机械搅拌力及由此产生的空气动力,使细粉状料在机内连续实现混合,成粒、球化、致密等过程,从而达到造粒的目的。颗粒形状为球形,球形度≥0.7,粒径一般在0.3-3毫米之间,成粒率高,颗粒直径的大小可通过物料混合量和主轴转速适当调节,通常混合量越低,转速越高,颗粒越小,反之亦然。

应用范围:该机尤其适用于轻质细粉物料的造粒。细粉物料的基本微粒越细,颗粒的球形度越高,成球质量越好。一般要求物料造粒前的粒度应小于300目为宜,典型应用物料:鸡粪、猪粪、牛粪、炭里、陶土、高岭土等

Use and Features:

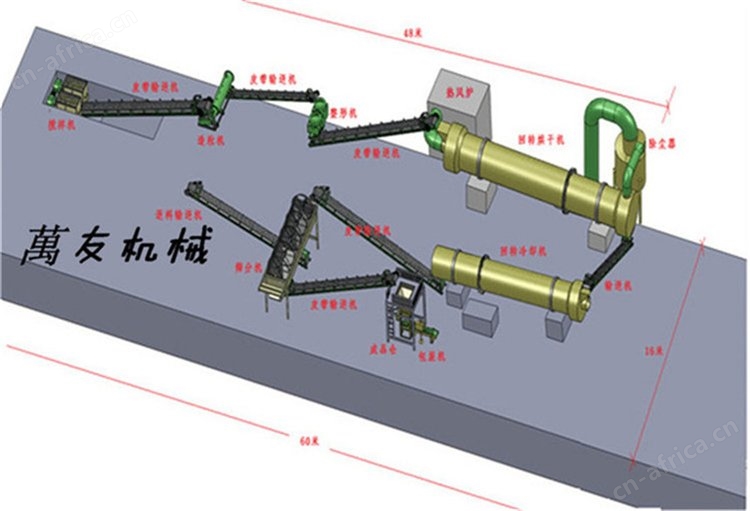

The New Type Organic Fertilizer Granulator Machine utilize high speed rotary mechanical stirring force and the resulting friction force to make the powdery material continuous mixing、granulating、balling and intensifying inside the machine, to achieve the purpose of material granulation. It is mainly used for granulate various organic materials after fermentation. It breaks through the traditional organic material granulate technology, and do not need to dry the raw materials. The raw materials can be granulated at about 30%-40% moisture content. The diameter of the finished product is generally between 0.3-5 mm, granulation rate is above 85%, the content of organic matter is high. Meanwhile, the size of the products can be adjusted by the mixture quantity of material and the spindle speed. Lower mixing amount and higher spindle speed will get smaller products, and vice versa. Application: The machine is especially suitable for granulate light fine powder materials. The smaller size material can get higher granulation rate and better quality products. Typical application materials: chicken manure, pig manure, cow dung, carbon black, clay, kaolin and so on.

所有评论仅代表网友意见,与本站立场无关。