2025年12月26日 09:28:21 来源:深圳市晶诺威科技有限公司 >> 进入该公司展台 阅读量:9

I Ask the Product Manager: Are real rock crystals used for production of oscillating quartz crystals? What material the quartz blanks are made of and what steps are necessary for a quartz blank with a certain frequency to be created from a quartz block.

我问产品经理:真正的水晶是否用于生产频率振荡的石英晶体?石英坯料是由什么材料制成的,以及从石英块中制造出一定频率的石英坯料需要哪些步骤。

For instance,we are now at the following point in the process leading up to the finished component: the quartz blank has been produced, even the electrode has already been vaporized and the frequency has been checked. The blank must now be installed into the housing. It sounds simple, but even here there are one or two points to consider so that the final result is a high quality and durable quartz.

假如我们现在正处于成品部件过程的以下阶段:石英毛坯已经生产出来,甚至电极也已经汽化(即:被银工序)并检查了频率。现在必须将石英晶片安装到外壳中。这听起来很简单,但即使在这里,也需要考虑一两点,以便最终结果是高质量和耐用的石英晶振产品。

Mounting into the housing 安装到外壳中

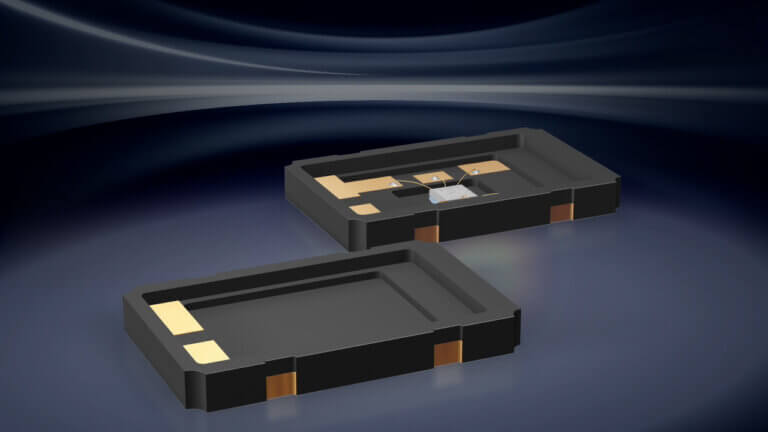

To mount the blanks into the housing, the housing base is first of all coated with conductive adhesive. The next step is to affix the quartz blank.

为了将晶片安装到外壳中,首先在外壳底座上涂上导电粘合剂(导电胶)。下一步是粘住石英晶片(点胶)。

Mounting of a quartz blank in the housing

The final frequency adjustment 最后的频率调整

Now the frequency is adjusted one last time. Using two different methods, the target frequency is adjusted if necessary. On the one hand, additional electrode material can be vapor-deposited if the frequency is too high. This step decreases the frequency. Alternatively, partial removal of the electrode material with plasma can increase the frequency.

现在进行次频率调整。使用两种不同的方法,可以对目标频率进行微调。一方面,如果频率过高,可以通过喷银方式增加电极以降低频率。反之,如果频率过低,可以用等离子去除部分电极材料(银)以增加其频率。

Final frequency adjustment

The housing is sealed 外壳密封

Next, the housing is sealed. There are several methods for this. The “Seam Seal” method is often used. In this process, the metal lid and packaging are welded together with electrodes.

接下来,密封外壳:抽真空、充氮气。晶诺威科技采用“滚边焊”方式进行外壳密封。

With the seam seal method the housing is sealed

The final stages 最后阶段

The quartzes are marked with the help of lasers before they are subjected to final testing, packing and shipping.

石英晶振产品进行最终测试、激光丝印、包装和运输。

Now the quartz crystal is finished and it can be mounted on the plate.

现在石英晶体产品已经完成,可以安装在电路板上了。