干式电机长轴/轴流深井消防泵组参照中华人民共和国消防泵标准GB6245-2006 《消防泵性能要求和试验方法》之规定,参考现代优秀的水利模型设计而成,专门用于消防系统的离心泵;产品经国家消防装备质量监督检测中心测试合格,获得消防产品认可证书。产品主要用于消防系统增压送水,也可用于厂矿给排水,产品性能达到国内同类产品的水平。

深井消防泵主要用于工矿企业、工程建设、高层大厦等固定消防系统中的消防栓灭火、自动喷淋灭火等消防系统,可供输送不含固体颗粒的清水及化学性质类似于水的介质,又可用于生活、生产共用给水系统及建筑、市政给排水等。

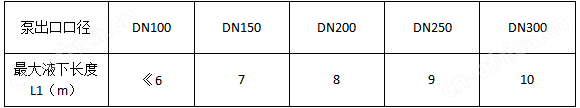

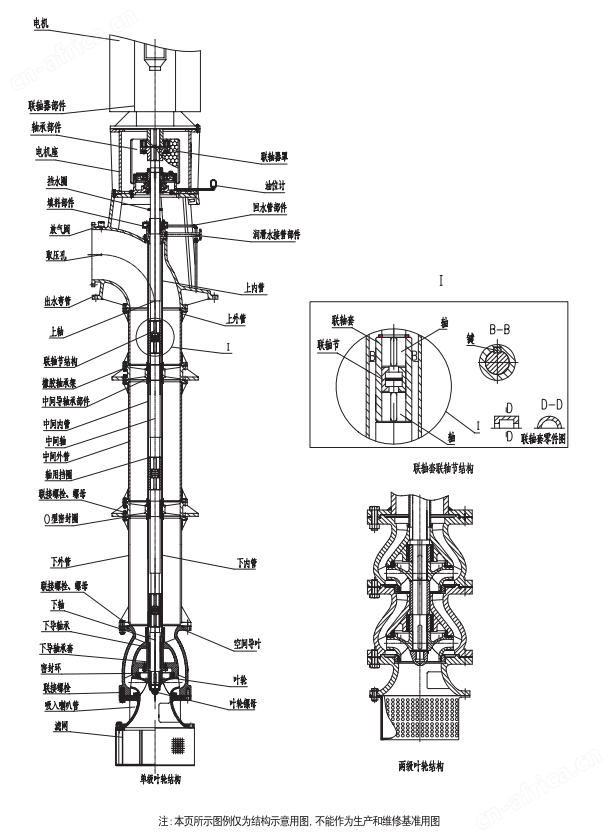

该泵在设计时考虑到长轴泵的结构特点、用户的使用条件及对可靠性的要求和市场需求情况,规划泵的口径100mm~300mm;同时由于泵自身的结构特点限制,为确保产品的运行可靠性,对各口径的大液下长度进行限制,如下表所示:

注:大液下长度L1指安装基础面至滤网底面的长度,超出范围可定制。

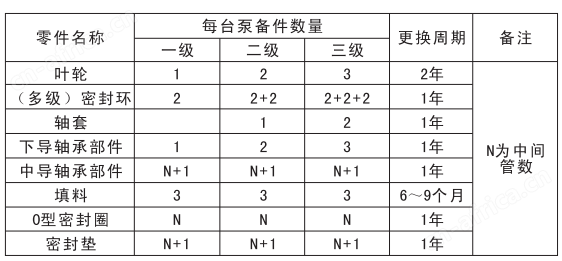

XBD-RJC长轴立式消防泵备件一览表

序号 | 型号规格 | 额定流量 (L/s) | 额定压力 (Mpa) | 额定功率 (kw) | 额定转速 (r/min) | 口径 mm | 工作压力(≤Mpa) | 150%额定流量的压力(≥Mpa) |

1 | XBD3.3/5GJ-HK | 5 | 0.33 | 3 | 2900 | 50 | 0.462 | 0.215 |

2 | XBD4.0/5GJ-HK | 5 | 0.40 | 4 | 2900 | 50 | 0.560 | 0.260 |

3 | XBD6.0/5GJ-HK | 5 | 0.60 | 5.5 | 2900 | 50 | 0.840 | 0.390 |

4 | XBD8.0/5GJ-HK | 5 | 0.80 | 7.5 | 2900 | 50 | 1.120 | 0.520 |

5 | XBD10.0/5GJ-HK | 5 | 1.00 | 11 | 2900 | 50 | 1.400 | 0.650 |

6 | XBD12.0/5GJ-HK | 5 | 1.20 | 15 | 2900 | 50 | 1.680 | 0.780 |

7 | XBD14.0/5GJ-HK | 5 | 1.40 | 15 | 2900 | 50 | 1.960 | 0.910 |

8 | XBD16.3/5GJ-HK | 5 | 1.63 | 15 | 2900 | 50 | 2.282 | 1.060 |

9 | XBD3.2/10GJ-HK | 10 | 0.32 | 5.5 | 2900 | 65 | 0.448 | 0.208 |

10 | XBD4.2/10GJ-HK | 10 | 0.42 | 7.5 | 2900 | 65 | 0.588 | 0.273 |

11 | XBD5.0/10GJ-HK | 10 | 0.50 | 7.5 | 2900 | 65 | 0.700 | 0.325 |

12 | XBD6.0/10GJ-HK | 10 | 0.60 | 11 | 2900 | 65 | 0.840 | 0.390 |

13 | XBD8.4/10GJ-HK | 10 | 0.84 | 15 | 2900 | 65 | 1.176 | 0.546 |

14 | XBD9.6/10GJ-HK | 10 | 0.96 | 15 | 2900 | 65 | 1.344 | 0.624 |

15 | XBD10.0/10GJ-HK | 10 | 1.00 | 18.5 | 2900 | 65 | 1.400 | 0.650 |

16 | XBD11.0/10GJ-HK | 10 | 1.10 | 18.5 | 2900 | 65 | 1.540 | 0.715 |

17 | XBD12.0/10GJ-HK | 10 | 1.20 | 18.5 | 2900 | 65 | 1.680 | 0.780 |

18 | XBD13.0/10GJ-HK | 10 | 1.30 | 22 | 2900 | 65 | 1.820 | 0.845 |

19 | XBD14.4/10GJ-HK | 10 | 1.44 | 22 | 2900 | 65 | 2.016 | 0.936 |

20 | XBD15.6/10GJ-HK | 10 | 1.56 | 22 | 2900 | 65 | 2.184 | 1.014 |

21 | XBD17.0/10GJ-HK | 10 | 1.70 | 30 | 2900 | 65 | 2.380 | 1.105 |

22 | XBD18.0/10GJ-HK | 10 | 1.80 | 30 | 2900 | 65 | 2.520 | 1.170 |

23 | XBD3.6/15GJ-HK | 15 | 0.36 | 11 | 2900 | 80 | 0.504 | 0.234 |

24 | XBD5.0/15GJ-HK | 15 | 0.50 | 11 | 2900 | 80 | 0.700 | 0.325 |

25 | XBD6.0/15GJ-HK | 15 | 0.60 | 15 | 2900 | 80 | 0.840 | 0.390 |

26 | XBD7.2/15GJ-HK | 15 | 0.72 | 15 | 2900 | 80 | 1.008 | 0.468 |

27 | XBD8.4/15GJ-HK | 15 | 0.84 | 18.5 | 2900 | 80 | 1.176 | 0.546 |

28 | XBD9.6/15GJ-HK | 15 | 0.96 | 22 | 2900 | 80 | 1.344 | 0.624 |

29 | XBD11.0/15GJ-HK | 15 | 1.10 | 30 | 2900 | 80 | 1.540 | 0.715 |

30 | XBD12.0/15GJ-HK | 15 | 1.20 | 30 | 2900 | 80 | 1.680 | 0.780 |

31 | XBD13.0/15GJ-HK | 15 | 1.30 | 30 | 2900 | 80 | 1.820 | 0.845 |

32 | XBD14.0/15GJ-HK | 15 | 1.40 | 37 | 2900 | 80 | 1.960 | 0.910 |

33 | XBD15.6/15GJ-HK | 15 | 1.56 | 37 | 2900 | 80 | 2.184 | 1.014 |

34 | XBD17.0/15GJ-HK | 15 | 1.70 | 45 | 2900 | 80 | 2.380 | 1.105 |

35 | XBD18.2/15GJ-HK | 15 | 1.82 | 45 | 2900 | 80 | 2.548 | 1.183 |

36 | XBD20.0/15GJ-HK | 15 | 2.00 | 45 | 2900 | 80 | 2.800 | 1.300 |

37 | XBD3.3/20GJ-HK | 20 | 0.33 | 11 | 2900 | 100 | 0.462 | 0.215 |

38 | XBD4.4/20GJ-HK | 20 | 0.44 | 15 | 2900 | 100 | 0.616 | 0.286 |

39 | XBD5.5/20GJ-HK | 20 | 0.55 | 18.5 | 2900 | 100 | 0.770 | 0.358 |

40 | XBD6.6/20GJ-HK | 20 | 0.66 | 22 | 2900 | 100 | 0.924 | 0.429 |

41 | XBD8.0/20GJ-HK | 20 | 0.80 | 30 | 2900 | 100 | 1.120 | 0.520 |

42 | XBD9.0/20GJ-HK | 20 | 0.90 | 37 | 2900 | 100 | 1.260 | 0.585 |

43 | XBD10.0/20GJ-HK | 20 | 1.00 | 37 | 2900 | 100 | 1.400 | 0.650 |

44 | XBD11.0/20GJ-HK | 20 | 1.10 | 37 | 2900 | 100 | 1.540 | 0.715 |

45 | XBD12.1/20GJ-HK | 20 | 1.21 | 45 | 2900 | 100 | 1.694 | 0.787 |

46 | XBD14.0/20GJ-HK | 20 | 1.40 | 55 | 2900 | 100 | 1.960 | 0.910 |

47 | XBD16.0/20GJ-HK | 20 | 1.60 | 55 | 2900 | 100 | 2.240 | 1.040 |

48 | XBD18.0/20GJ-HK | 20 | 1.80 | 75 | 2900 | 100 | 2.520 | 1.170 |

49 | XBD20.0/20GJ-HK | 20 | 2.00 | 75 | 2900 | 100 | 2.800 | 1.300 |

50 | XBD3.2/25GJ-HK | 25 | 0.32 | 11 | 2900 | 100 | 0.448 | 0.208 |

51 | XBD4.2/25GJ-HK | 25 | 0.42 | 15 | 2900 | 100 | 0.588 | 0.273 |

52 | XBD5.3/25GJ-HK | 25 | 0.53 | 18.5 | 2900 | 100 | 0.742 | 0.345 |

53 | XBD6.3/25GJ-HK | 25 | 0.63 | 22 | 2900 | 100 | 0.882 | 0.410 |

54 | XBD7.3/25GJ-HK | 25 | 0.73 | 30 | 2900 | 100 | 1.022 | 0.475 |

55 | XBD8.4/25GJ-HK | 25 | 0.84 | 37 | 2900 | 100 | 1.176 | 0.546 |

56 | XBD10.0/25GJ-HK | 25 | 1.00 | 37 | 2900 | 100 | 1.400 | 0.650 |

57 | XBD11.0/25GJ-HK | 25 | 1.10 | 45 | 2900 | 100 | 1.540 | 0.715 |

58 | XBD12.0/25GJ-HK | 25 | 1.20 | 45 | 2900 | 100 | 1.680 | 0.780 |

59 | XBD14.0/25GJ-HK | 25 | 1.40 | 55 | 2900 | 100 | 1.960 | 0.910 |

60 | XBD16.0/25GJ-HK | 25 | 1.60 | 55 | 2900 | 100 | 2.240 | 1.040 |

61 | XBD18.5/25GJ-HK | 25 | 1.85 | 75 | 2900 | 100 | 2.590 | 1.203 |

62 | XBD3.6/30GJ-HK | 30 | 0.36 | 15 | 2900 | 100 | 0.504 | 0.234 |

63 | XBD5.0/30GJ-HK | 30 | 0.50 | 22 | 2900 | 100 | 0.700 | 0.325 |

64 | XBD6.0/30GJ-HK | 30 | 0.60 | 30 | 2900 | 100 | 0.840 | 0.390 |

65 | XBD7.2/30GJ-HK | 30 | 0.72 | 30 | 2900 | 100 | 1.008 | 0.468 |

66 | XBD8.0/30GJ-HK | 30 | 0.80 | 37 | 2900 | 100 | 1.120 | 0.520 |

67 | XBD9.0/30GJ-HK | 30 | 0.90 | 45 | 2900 | 100 | 1.260 | 0.585 |

68 | XBD11.0/30GJ-HK | 30 | 1.10 | 45 | 2900 | 100 | 1.540 | 0.715 |

69 | XBD13.0/30GJ-HK | 30 | 1.30 | 55 | 2900 | 100 | 1.820 | 0.845 |

70 | XBD14.5/30GJ-HK | 30 | 1.45 | 75 | 2900 | 100 | 2.030 | 0.943 |

71 | XBD16.2/30GJ-HK | 30 | 1.62 | 75 | 2900 | 100 | 2.268 | 1.053 |

72 | XBD18.0/30GJ-HK | 30 | 1.80 | 90 | 2900 | 100 | 2.520 | 1.170 |

73 | XBD20.0/30GJ-HK | 30 | 2.00 | 90 | 2900 | 100 | 2.800 | 1.300 |

74 | XBD3.2/35GJ-HK | 35 | 0.32 | 18.5 | 2900 | 125 | 0.448 | 0.208 |

75 | XBD5.0/35GJ-HK | 35 | 0.50 | 30 | 2900 | 125 | 0.700 | 0.325 |

76 | XBD6.5/35GJ-HK | 35 | 0.65 | 37 | 2900 | 125 | 0.910 | 0.423 |

77 | XBD8.0/35GJ-HK | 35 | 0.80 | 45 | 2900 | 125 | 1.120 | 0.520 |

78 | XBD10.0/35GJ-HK | 35 | 1.00 | 55 | 2900 | 125 | 1.400 | 0.650 |

79 | XBD11.2/35GJ-HK | 35 | 1.12 | 75 | 2900 | 125 | 1.568 | 0.728 |

80 | XBD13.0/35GJ-HK | 35 | 1.30 | 75 | 2900 | 125 | 1.820 | 0.845 |

81 | XBD15.0/35GJ-HK | 35 | 1.50 | 90 | 2900 | 125 | 2.100 | 0.975 |

82 | XBD16.0/35GJ-HK | 35 | 1.60 | 90 | 2900 | 125 | 2.240 | 1.040 |

83 | XBD18.0/35GJ-HK | 35 | 1.80 | 110 | 2900 | 125 | 2.520 | 1.170 |

84 | XBD19.2/35GJ-HK | 35 | 1.92 | 110 | 2900 | 125 | 2.688 | 1.248 |

85 | XBD20.0/35GJ-HK | 35 | 2.00 | 110 | 2900 | 125 | 2.800 | 1.300 |

86 | XBD3.2/40GJ-HK | 40 | 0.32 | 18.5 | 2900 | 125 | 0.448 | 0.208 |

87 | XBD4.8/40GJ-HK | 40 | 0.48 | 30 | 2900 | 125 | 0.672 | 0.312 |

88 | XBD6.0/40GJ-HK | 40 | 0.60 | 37 | 2900 | 125 | 0.840 | 0.390 |

89 | XBD8.0/40GJ-HK | 40 | 0.80 | 45 | 2900 | 125 | 1.120 | 0.520 |

90 | XBD9.0/40GJ-HK | 40 | 0.90 | 55 | 2900 | 125 | 1.260 | 0.585 |

91 | XBD11.0/40GJ-HK | 40 | 1.10 | 75 | 2900 | 125 | 1.540 | 0.715 |

92 | XBD12.0/40GJ-HK | 40 | 1.20 | 75 | 2900 | 125 | 1.680 | 0.780 |

93 | XBD14.0/40GJ-HK | 40 | 1.40 | 90 | 2900 | 125 | 1.960 | 0.910 |

94 | XBD15.0/40GJ-HK | 40 | 1.50 | 90 | 2900 | 125 | 2.100 | 0.975 |

95 | XBD16.5/40GJ-HK | 40 | 1.65 | 110 | 2900 | 125 | 2.310 | 1.073 |

96 | XBD18.0/40GJ-HK | 40 | 1.80 | 110 | 2900 | 125 | 2.520 | 1.170 |

97 | XBD20.0/40GJ-HK | 40 | 2.00 | 132 | 2900 | 125 | 2.800 | 1.300 |

98 | XBD3.2/50GJ-HK | 50 | 0.32 | 22 | 2900 | 125 | 0.448 | 0.208 |

99 | XBD4.5/50GJ-HK | 50 | 0.45 | 37 | 2900 | 125 | 0.630 | 0.293 |

100 | XBD6.0/50GJ-HK | 50 | 0.60 | 45 | 2900 | 125 | 0.840 | 0.390 |

101 | XBD8.0/50GJ-HK | 50 | 0.80 | 55 | 2900 | 125 | 1.120 | 0.520 |

102 | XBD9.0/50GJ-HK | 50 | 0.90 | 75 | 2900 | 125 | 1.260 | 0.585 |

103 | XBD10.5/50GJ-HK | 50 | 1.05 | 75 | 2900 | 125 | 1.470 | 0.683 |

104 | XBD12.0/50GJ-HK | 50 | 1.20 | 90 | 2900 | 125 | 1.680 | 0.780 |

105 | XBD14.0/50GJ-HK | 50 | 1.40 | 90 | 2900 | 125 | 1.960 | 0.910 |

106 | XBD15.0/50GJ-HK | 50 | 1.50 | 110 | 2900 | 125 | 2.100 | 0.975 |

107 | XBD17.0/50GJ-HK | 50 | 1.70 | 110 | 2900 | 125 | 2.380 | 1.105 |

108 | XBD18.0/50GJ-HK | 50 | 1.80 | 132 | 2900 | 125 | 2.520 | 1.170 |

109 | XBD20.0/50GJ-HK | 50 | 2.00 | 132 | 2900 | 125 | 2.800 | 1.300 |

110 | XBD4.0/60GJ-HK | 60 | 0.40 | 37 | 2900 | 125 | 0.560 | 0.260 |

111 | XBD5.0/60GJ-HK | 60 | 0.50 | 45 | 2900 | 125 | 0.700 | 0.325 |

112 | XBD6.0/60GJ-HK | 60 | 0.60 | 55 | 2900 | 125 | 0.840 | 0.390 |

113 | XBD8.0/60GJ-HK | 60 | 0.80 | 75 | 2900 | 125 | 1.120 | 0.520 |

114 | XBD10.0/60GJ-HK | 60 | 1.00 | 90 | 2900 | 125 | 1.400 | 0.650 |

115 | XBD12.0/60GJ-HK | 60 | 1.20 | 110 | 2900 | 125 | 1.680 | 0.780 |

116 | XBD14.0/60GJ-HK | 60 | 1.40 | 132 | 2900 | 125 | 1.960 | 0.910 |

117 | XBD16.0/60GJ-HK | 60 | 1.60 | 160 | 2900 | 125 | 2.240 | 1.040 |

118 | XBD18.0/60GJ-HK | 60 | 1.80 | 160 | 2900 | 125 | 2.520 | 1.170 |

119 | XBD20.0/60GJ-HK | 60 | 2.00 | 200 | 2900 | 125 | 2.800 | 1.300 |

120 | XBD3.0/70GJ-HK | 70 | 0.30 | 37 | 2900 | 150 | 0.420 | 0.195 |

121 | XBD4.0/70GJ-HK | 70 | 0.40 | 45 | 2900 | 150 | 0.560 | 0.260 |

122 | XBD5.0/70GJ-HK | 70 | 0.50 | 55 | 2900 | 150 | 0.700 | 0.325 |

123 | XBD6.0/70GJ-HK | 70 | 0.60 | 75 | 2900 | 150 | 0.840 | 0.390 |

124 | XBD7.2/70GJ-HK | 70 | 0.72 | 90 | 2900 | 150 | 1.008 | 0.468 |

125 | XBD8.2/70GJ-HK | 70 | 0.82 | 110 | 2900 | 150 | 1.148 | 0.533 |

126 | XBD10.0/70GJ-HK | 70 | 1.00 | 132 | 2900 | 150 | 1.400 | 0.650 |

127 | XBD13.0/70GJ-HK | 70 | 1.30 | 160 | 2900 | 150 | 1.820 | 0.845 |

128 | XBD15.0/70GJ-HK | 70 | 1.50 | 200 | 2900 | 150 | 2.100 | 0.975 |

129 | XBD3.0/80GJ-HK | 80 | 0.30 | 37 | 2900 | 150 | 0.420 | 0.195 |

130 | XBD4.0/80GJ-HK | 80 | 0.40 | 45 | 2900 | 150 | 0.560 | 0.260 |

131 | XBD5.0/80GJ-HK | 80 | 0.50 | 55 | 2900 | 150 | 0.700 | 0.325 |

132 | XBD6.0/80GJ-HK | 80 | 0.60 | 75 | 2900 | 150 | 0.840 | 0.390 |

133 | XBD7.2/80GJ-HK | 80 | 0.72 | 90 | 2900 | 150 | 1.008 | 0.468 |

134 | XBD8.2/80GJ-HK | 80 | 0.82 | 110 | 2900 | 150 | 1.148 | 0.533 |

135 | XBD10.0/80GJ-HK | 80 | 1.00 | 132 | 2900 | 150 | 1.400 | 0.650 |

136 | XBD13.0/80GJ-HK | 80 | 1.30 | 160 | 2900 | 150 | 1.820 | 0.845 |

137 | XBD15.0/80GJ-HK | 80 | 1.50 | 200 | 2900 | 150 | 2.100 | 0.975 |

138 | XBD3.0/90GJ-HK | 90 | 0.30 | 45 | 2900 | 200 | 0.420 | 0.195 |

139 | XBD4.0/90GJ-HK | 90 | 0.40 | 75 | 2900 | 200 | 0.560 | 0.260 |

140 | XBD6.0/90GJ-HK | 90 | 0.60 | 90 | 2900 | 200 | 0.840 | 0.390 |

141 | XBD8.0/90GJ-HK | 90 | 0.80 | 110 | 2900 | 200 | 1.120 | 0.520 |

142 | XBD9.0/90GJ-HK | 90 | 0.90 | 132 | 2900 | 200 | 1.260 | 0.585 |

143 | XBD10.2/90GJ-HK | 90 | 1.02 | 160 | 2900 | 200 | 1.428 | 0.663 |

144 | XBD12.0/90GJ-HK | 90 | 1.20 | 200 | 2900 | 200 | 1.680 | 0.780 |

145 | XBD3.0/100GJ-HK | 100 | 0.30 | 45 | 2900 | 200 | 0.420 | 0.195 |

146 | XBD4.0/100GJ-HK | 100 | 0.40 | 75 | 2900 | 200 | 0.560 | 0.260 |

147 | XBD6.0/100GJ-HK | 100 | 0.60 | 90 | 2900 | 200 | 0.840 | 0.390 |

148 | XBD8.0/100GJ-HK | 100 | 0.80 | 132 | 2900 | 200 | 1.120 | 0.520 |

149 | XBD9.0/100GJ-HK | 100 | 0.90 | 160 | 2900 | 200 | 1.260 | 0.585 |

150 | XBD9.8/100GJ-HK | 100 | 0.98 | 200 | 2900 | 200 | 1.372 | 0.637 |

成套供应范围

1、泵

2、电机

3、联轴器、联轴器套

4、底座、地脚螺栓

5、润滑冷却水接管,油位计

6、备件(根据客户需要)

订货须知

1.为了按照使用条件正确选用泵的规格、零部件材料,订货时用户应向我方提供所需的流量及扬程,液下深度、介质情况等相关信息。

2、对原动机有特殊要求时,用户应说明现场条件。

3、若用户对轴封及泄露物有其它要求,订货时应说明。

4、长轴消防泵若需要润滑冷却水,润滑冷却水及其供水系统由用户自备,业务员须与用户就润滑冷却水的供应的压力,流量进行必要沟通,以免造成不必要的误会。

5、长轴泵的装卸,安装应采用专用吊装设备以避免由于吊装不合理造成泵的损坏。

所有评论仅代表网友意见,与本站立场无关。